One of the most confusing questions I often get asked by many people intending to buy an air compressor is " what size air compressor do I need for my air tools?". Air compressors indeed come in a wide variety of sizes what makes intended buyers confused about determining the particular size.

But truly speaking, if you pay a little more attention to some factors, for example, intended application, project type, required amount of gas, source of electricity, portability, noise level, and so on, it will be an easy task to obtain the suitable air compressor, and no confusions will affect your choice.

This article, however, will explain to you several things you need to consider when evaluating the size of the air compressor you are going to select from a hundred sizes available on the market today. So keep on reading carefully with patience.

Considerations for sizing air compressor

Projects Type

What helps you most find the exact size of air pressure is knowing what types of projects will be done with the air compressor. If it is going to be occasional use at your home garage, you will buy a best small compressor. For large projects like construction work and manufacturing industry, you need a big size air compressor that can deliver an ample amount of gas with required pressure.

Types of air tools

There are many tools that run on gas. Not all do they require the same amount of pressure to operate. While some work with low air pressure, others need high pressure. For example, most nail guns need pressure of around 120 PSI, whereas air guns work with at least 3000 PSI. That means pressure requirements vary with different tools, hence requiring different sizes of air compressors.

So It’s crucial to determine how much pressure needed exactly for your air tools. Fortunately, air tools manufacturers set the required parameters which are usually mentioned on the box. Before choosing an air compressor, have a look at the pressure that your tools require. Then specify how big or small compressor you need accordingly.

Does the tank size matter?

When it comes to deciding how big or small air compressor needed for gas projects, the tank size becomes an essential factor to consider. Although the tank size has no impact on flow rate and pressure level, it determines how long the air compressor can power the tools before the motor of the compressor needs to run again.

The tank capacity is defined based on the CFM. The bigger the tank, the more compressed air available in the tank ready to supply to the air tools. Usually, the gallon is used as a unit to measure the tank size, ranging from 1 gallon to up to 60 gallons or even more. Some instruments, such as paint sprayers and sander, demand continuous flow; therefore, a large tank is needed. The smaller tanks are most suitable for the equipment not requiring a continuous flow of pressurized gas such as air nailers.

Electricity Source

An air compressor can run on both the gasoline and electricity. There is no issue with one powered by gas. But if you opt for an electric one, the availability of required electricity must be considered. The standard home outlet is sufficient for smaller compressors designed for home garage. But larger compressors with high power motor require high voltage to run. The more powerful compressor you choose, the higher the voltage you have to source to power the motor.

Space to place the air compressor

Of course, the place to be used to set the air compressor affects the selection of compressor size. Let me tell you how this matters. The compressors having large tanks occupy more space than those with small tanks. If you don’t have enough space, pancake portable tanks are a good option for you. They range from 3-6 gallons. For those who have no space limitation, vertical pontoon tanks are an ideal choice. That’s why it’s worth to think how much space you have for installation before choosing an air compressor.

Noise Level

Currently, the noise levels created by compressors range from 40 to 90 decibels. We know that when the noise level is more than 80 decibels, it causes hearing loss. Therefore it’s worth to have a look at the noise level. And there is, of course, a relation between the size of the compressor and the amount of noise.

Of all the factors responsible for making noise, compressor size plays an important role. Maybe you have noticed that all the inflators tend to be intolerably noisy. Do you know why? This is because of their compact structure. Since the mini piston inside the small inflator runs faster with higher rpm, an extreme level of noise generated. In a comparison, compressors with more moving parts such as reciprocating system are noisier than those with few or one moving part.

Portable or Stationary?

Last but not least, how large or small the air compressor you are going to choose is mainly dependent on your purpose. If it is going to be occasional and multipurpose applications at home garage, a portable small air compressor is enough to meet your daily requirements. In this consideration, pancake and twin stack design air compressors will work wonder.

For a particular work such as painting in an auto body shop, larger compressors are best suited which often tend to be stationary. No doubt that electric-powered compressors are are compact and consume less space. Gas-powered ones are usually large in overall size due to the engine added to generate the power. Nowadays, some manufacturers initiated wheelbarrow-style to move easily. In a nutshell, the more powerful the compressor, the larger the overall size is, especially tank size, thus occupying more space.

Here is the video explanation to size Your First Air Compressor

Guide on how to size Air compressor for Particular air tools

To simplify the technique of sizing air compressor, I am going to reveal how to size a compressor for particular pneumatic tools. This will help you find the precise idea about PSI, CFM, and HP requirements for every type of air tool.

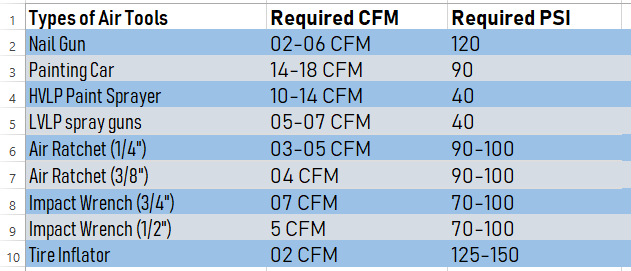

Required CFM and PSI Chart for Different Types of Air Tools

What size air compressor do I need for an impact wrench?

Among three types of impact wrenches available, pneumatic impact wrenches are the most common and popular. As the name implies, you are supposed to assume that they are powered by compressed air. That means they require an air compressor to supply pressurized gas to power them. But how much pressure and flow an impact wrench needs is arguably a common question. Consequently, sizing an air compressor for an impact wrench is crucial.

All you need to predict the size of the compressor is to have a closed look at three main criterions. The first and foremost aspect is cubic feet per minute. The CFM requirement for most impact wrench ranges between 3 and 10. In general, the amount of gas flow to run an impact wrench depends on its size.

The larger the impact wrench in size, the higher the CFM is required. For instance, a compressor capable of providing 5 CFM can run 1/2 inch impact wrench like The Porter Cable Impact Wrench. On the other hand, a 3/4 inch larger impact wrench must need 7 CFM to work smoothly.

Secondly, the horsepower is a critical factor you have to consider to narrow down the compressor size. Since not all are compressors designed with the same power, you must be aware of whether the power is sufficient for your impact wrench or not. The air compressors with 1 to 3 HP are suitable for any impact wrench. A 3/8 inch mini air wrench can be run off 1 HP smaller compressor. The horsepower should be determined in such a way so that your air tool is not affected either by under-power or over-power.

Then you need to take PSI into account to anticipate the compressor size. Usually, almost all sizes of impact wrenches operate at 70 to 100 PSI. So there is not that much problem with PSI here because even a small compressor can produce 120 PSI effortlessly.

What size air compressor do I need for a paint sprayer?

When it comes to painting with an air sprayer, maintaining the proper airflow and air pressure is the yardstick to get the quality painting. Let me disclose how these two parameters affect the painting quality. CFM impact on spray paint.

Painting with lower CFM than a pneumatic paint sprayer needs affects the finishing quality. Lower CFM causes poor coating performance. Due to this faulty finish, all painted area doesn’t look the same, one place is better painted, and another is not. In addition to this, if the CFM is lower than the requirement, you cannot paint for a long time at a stretch. This also results in inappropriate painting

The affection of PSI in spray painting

Both the higher pressure and lower pressure than the standard amount have some severe impacts on paint spray. While spraying with lower pressure causes poor atomization and excessive painting, higher pressure reasons uneven paint concentration, resulting in a rough coating on the surface.

Required CFM and PSI for the air paint sprayer

Generally, most air sprayer mention how much their CFM and PSI consumption is. The CFM and PSI consumption depend on which airguns you choose since they come in either HVLP (High Volume, Low Pressure) or LVLP ( Low Volume, Low Pressure) based on the amount of airflow and pressure they consume. In case of paint sprayer, the CFM rating is higher compared to the pressure.

Though painting car requires higher flow and pressure which is something between 14-18 CFM at 90 PSI, most HVLP spray painters work with 10-14 CFM at 40 PSI whereas LVLP spray guns use 5-7 CFM at 40 PSI. Maybe you have noticed that there is no or little variation in pressure. That’s why experts say that spray paint is usually not a matter of pressure, but the volume of the air. What I would like to mean is that most of the air compressors can generate the amount PSI that most paint sprayers need to operate smoothly. All that matters most is CFM in spray painting.

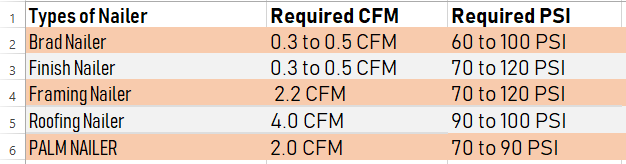

What size air compressor do I need for a nail gun?

Of all types of power nail guns, pneumatic nailers are the most common which run on compressed gas delivered by a compressor. Unlike other air tools that require continuous air supply, they need a short burst of airflow to operate. That means they consume less amount of airflow. But not all nail guns need the same CFM and PSI. I mean, each nailer has its requirement to drive the nail into the materials.

Neither too much nor too low gas flow is good for nailers. For example, insufficient air supply causes inefficient operation. Likewise, overflow can bring damage to the materials. That’s why you must respect both the airflow and air pressure while looking for an air compressor for your nail gun.

An air compressor capable of providing 120 PSI is fit for most of the nail guns. Sometimes, you may need more than this range when working with heavier nailer like framing gun.

But when it comes to the amount of airflow, The CFM requirement varies with the size of the nail. The larger the pin in size, the higher the CFM is demanded from the compressor. Usually, almost all nailers operate with 2-6 CFM ratings. Here, I have mentioned CFM requirements for all types of nail guns that will help you find the right air compressor for the specific nailer.

What size air compressor do I need to air up tires?

Though the proper tire inflation is significant for any vehicle, many, unfortunately, neglect this issue. As a result, life killing accidents often occur. Underinflation leads to too much tire wear and wasting gas that results in lower mileage, whereas overinflated tires cause bouncy riding. So you must inflate your car tires with the proper amount of pressure to avoid this kind of extreme situation.

However, all kinds of tires should not be inflated with an equal amount of pressure. Each has specific requirements. How much pressure do you need for inflating tires depends on types of tires and vehicles. Now let me tell you how big or small air compressor do you need for different kinds of vehicles tire

What size air compressor do I need for car tires?

According to the experts, the recommended air pressure for car tires is 32-35 PSI. That means almost any air compressor can deliver that much pressure easily. When it comes to CFM rating for vehicle tires, this is not a major concern as tires have valves. One important thing I need to share with you is that most manufacturers write the recommended PSI on the sidewall of the tire. This is the maximum pressure at cold temperatures. As far as the right pressure is concerned for tire inflation, the maximum is not the best. It’s better to go just below the maximum for proper inflation.

What size air compressor do I need for heavy vehicles tire?

Compared to car tires, heavy vehicles like trucks require more pressure as heavy vehicles use larger tires. Air pressure of 50-60 PSI can inflate larger tires used in large vehicles. Almost all air compressors can put out this amount of pressure effortlessly. Some heavy-duty vehicles like construction may need higher than this range.

What size air compressor do I need for automotive tools?

Automotive garages use a set of air tools such as tire inflator, impact wrench, grease gun, paint sprayer, and so on, which run on pressurized gas: each tool has specific CFM and PSI requirements. That’s why people ask how big air compressors they need for the automotive garage. Here is the solution.

As you need to work with all air tools required for an auto repair, you are not going to buy different compressors for different machines. All that you need to do is to add up the total CFM requirement of all tools and choose an air compressor able to put up that amount of gas flow to run a complete set of automotive tools.

Most auto garages and workshops need a total CFM of 70 to work with their basic air tools. With this flow rating, they use tire inflators, impact wrenches, washer, and oil pump.

In a word, all that you need to consider is what tools you will be using with an air compressor and what is their requirement and select the compressor accordingly. Hopefully, my research will help you determine how big or small your air compressor should be. And I think now it’s a simple issue for you to size an air compressor though it seemed too complicated before reading this article.

Olivia Archer provides in-depth coverage of air compressors, air compressor accessories, tire inflators and all things related to air compressors. She is a mechanical engineer and air compressor expert with a wealth of knowledge and experience in the industry.

Olivia’s articles are informative, well-researched and provide readers with valuable insights and information to help them make informed decisions when purchasing air compressors and accessories. She is passionate about the industry and is always looking for new ways to share her knowledge and expertise with readers. When she’s not writing for the website, Olivia can be found working on her own DIY projects, experimenting with different tools and techniques, and expanding her knowledge of the industry.