Fed up with intolerable noise made by your air compressor? Looking for ways to soundproof your home and office?

Like you, I was too disturbed with unwanted noise that would come from my air compressor, and I successfully fixed this problem. Now my home is soundproof; my baby sleeps; my neighbors live in a quiet environment, although my compressor is in use.

Today I will reveal some techniques I applied to quiet my air compressor. Hope this will help you cut down the amount of noise produced by your air compressor to a tolerable level.

Recently, some companies have developed a few quiet compressors, but unfortunately, they are too much expensive. And it’s noticeable that the quieter the compressors, the costlier they tend to be.

So, it’s better to make your compressors quieter with some simple techniques rather than investing more money in buying a quiet compressor.

7 Ways to make your air compressor quieter

1. Extending the intake to outside

The air intake part is responsible for a significant amount of the noise produced by an air compressor. If you can extend the intake and move it outside from where the compressor is, your house or office will be remarkably quiet. And this is the simplest and the most economical option to do.

To be able to do this, all you need to do is to buy rubber hose and push one end of the hose into the compressor’s intake firmly and then extend the other end outside the house.

The most effective way to extend the hose outside is to pass it through a hole that can be made with a drill machine. Moving the hosepipe through the door or window will not be as effective as through the hole.

2. Installing the silencer on the intake

As I said earlier, more than half of the total noise made by an air compressor comes from the intake valve. This is because the intake valve does the entire air suction. However, there is another way to suppress this extreme noise coming from the intake valve.

This method is all about installing a muffler on the intake. A muffler is a tool specially designed to put on the intake to reduce the noise when your compressor is quite louder.

How you have to install the muffler is to connect the one end of the air hose to the intake valve and another end to muffler. You can use the second air hose in the same way if it is double stage compressor. This will give you a double effect.

3. Wrapping the compressor with sound-dampening materials

Covering the compressor with sound-dampening materials will help suppress the noise coming from it. This can be done with either rubber if you spend a little more money or mat if you are on a tight budget.

The rubber seems to be a good sound insulator and can absorb sound. Insulating the compressor with thick rubber will work wonder as the sound-dampening device. Besides, the rubber doesn’t let the vibration made by motor convert into eco.

Though I only used rubber in the noise reduction process, some suggested me to use a carpet or mat as sound-absorbent materials. You can have a try with them.

4. Building soundproofing enclosure

One of the most effective techniques for silencing a louder compressor is placing it inside a soundproof enclosure while in operation. Compared to other solutions, this method is a little difficult but can give you the best result.

What is the key advantage of applying this system is the soundproof enclosure can be hand-made. All that you need to consider is to choose the right materials and good foam insulators to be used in building the box.

The tools you will need to make the box are a circular saw, a driller, some screws and nails, and adhesive. You can use plywood to build the box and cheap soundproof foam inside the box to suppress the noise.

Before making the box, take the right measurements of your air compressor and take a little allowance so that you can place the compressor easily inside the box. This will avoid the compressor from overheating too. You can also install an exhaust fan to reduce the heat generated by the compressor.

Now fix the box with screws and nails then attach the soundproof foam to the inside wall of the box with adhesive.

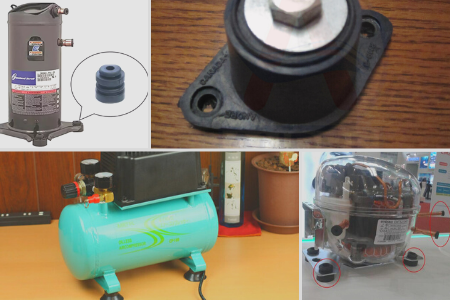

5. Placing rubber grommets between compressor’s mount and the floor

Vibration doesn’t directly cause noise but reasons the parts to create additional sound. When the air compressor is mounted on the floor, the vibration against the floor reaches the highest level.

Rubber is an ideal vibration absorbent and has an unbelievable sound insulating property. If you place a rubber grommet correctly, it will not the vibration go into the floor, resulting in sound reduction.

Rubber grommets are specially designed, which absorb the impact energy. They come in different sizes. You can choose one that suits best to your compressor.

6. Routine lubrication

The air compressors consist of many moving elements. In order to keep all the moving parts running smoothly, lubrication is inevitable. I do routine maintenance and lubrication to keep my compressor quiet and operate at maximum performance.

No or less lubrication causes friction among the moving parts, leading to extreme wear and tear. Once all this happens, the compressor begins to make noise.

Therefore, lubricating your compressor at an interval will noticeably reduce the noise level. Oil and grease are right lubricants. You can apply any of them to lubricate the moving elements of your compressor.

7. Tightening the loose parts

The last but not least, like any other machine, air compressors also have many screws and bolts. When these screws and bolts are loose over long time usage, they make extra noise due to vibration.

Besides, many other parts like clamps, pulleys, and cooler of a compressor go loose because these components are fixed with screws, nuts, and bolts.

Checking and tightening all loose parts routine wise will help you alleviate unwanted noise.

Here are a video guide for noise reduction for air compressors

Final Note

There is no denying factor that it’s almost impossible to silence an air compressor completely. But you are assured that applying the techniques described above can certainly bring the noise level down at a considerable amount. I can guarantee you as they worked wonder for me.

Olivia Archer provides in-depth coverage of air compressors, air compressor accessories, tire inflators and all things related to air compressors. She is a mechanical engineer and air compressor expert with a wealth of knowledge and experience in the industry.

Olivia’s articles are informative, well-researched and provide readers with valuable insights and information to help them make informed decisions when purchasing air compressors and accessories. She is passionate about the industry and is always looking for new ways to share her knowledge and expertise with readers. When she’s not writing for the website, Olivia can be found working on her own DIY projects, experimenting with different tools and techniques, and expanding her knowledge of the industry.